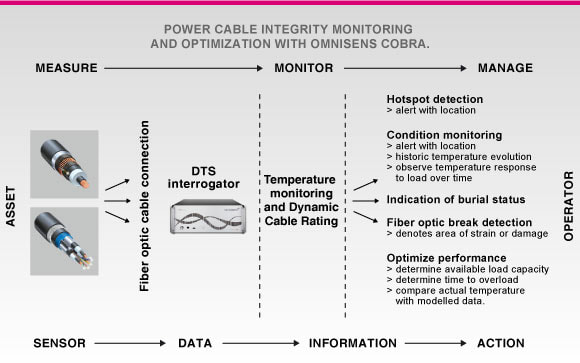

Power engineers are challenged to provide uninterrupted electricity supply at minimal financial and environmental cost, while fulfilling regulatory requirements, being Smart Grid compliant and cyber secure. How can Omnisens Cobra help in this challenge?

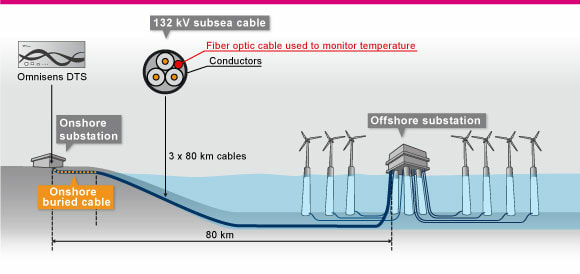

CONDITION MONITORINGIn both underground and subsea cables incipient faults often result in temperature events. Using optical fibers integrated into the power cable or laid close by, Distributed Temperature Sensing (DTS) helps detect changes and faults allowing the operator to intervene before the cable fails. It is suitable for deployment in any cable where an optical fiber is present, including HVDC, HVAC, export, inter-array, transmission and distribution.

PERFORMANCE AND DESIGN OPTIMIZATIONPower cable performance and design can be optimized using the Dynamic Cable Rating (DCR) module. (Note: DCR is also known as RTTR and DRS).

|

WHY USE OMNISENS COBRA?

Monitor condition and performance from the shortest to the longest cable

Omnisens Cobra fiber optic distributed sensing system provides:

|

|

-

What is Omnisens Cobra?

-

Underground cable monitoring

-

Subsea cable monitoring

-

Omnisens Service

<

>

Omnisens cobra is a modular fiber optic distributed sensing solution for power cable condition monitoring and performance optimization.

The system comprises:

Omnisens high performance distributed temperature sensing (dts)

Based on Brillouin or Raman scattering depending on the project requirements, DTS detects, locates and profiles small temperature changes along the entire length of a power cable continuously, in real time.

- Omnisens DITEST (Distributed Temperature and Strain Sensing) interrogators are based on Brillouin sensing using single mode optical fibers as the sensor. The DITEST is a DTS which provides effective monitoring of long cables, or where the sensing fiber experiences significant optical loss, with consistent spatial resolution. It detects temperature and/or strain. Due to manufacturing, transport and installation challenges of long cables, the sensing fiber may be placed under tension and strained. The affected cable sections can be successfully monitored for temperature using compensation techniques developed by Omnisens. Whether unintentionally detected or actively monitored for using an appropriate fiber optic sensor design, strain provides another insight into the power cable's condition. Knowing where strain exists or is developing, the operator can mitigate against the effects this may have. One or more dedicated servers are included for data processing and storage.

- Omnisens Raman DTS interrogators provide temperature monitoring of power cables using multimode optical fiber as the sensor. For many cables, particularly shorter, direct buried cables, this is an ideal solution.

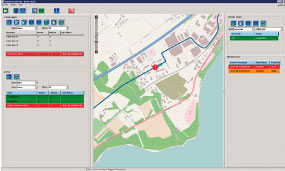

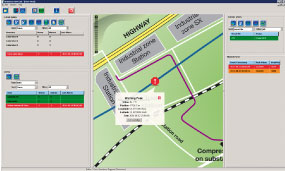

Omnisens map

|

An optional customizable graphical user interface, Omnisens Map provides a simple ‘see at a glance’ visualization of the entire asset, showing alerts and events.

Information from Omnisens Cobra Dynamic Cable Rating can be integrated into Omnisens Map, e.g.: position of lowest and highest monthly temperature. |

Dynamic cable rating.

The optional Dynamic Cable Rating (DCR) module establishes the relationship between load and temperature. This information helps manage the performance of the cable as well as providing ratings in emergency situations.

Dynamic Cable Rating uses algorithms based on IEC 60287 and 60853. The DCR calculates the conductor temperature based on the cable construction, electrical design, laying configuration and environment.

Knowing the temperature of the conductor and the load, the following predictions can be made:

(Note: DCR is also known as RTTR and DRS)

Dynamic Cable Rating uses algorithms based on IEC 60287 and 60853. The DCR calculates the conductor temperature based on the cable construction, electrical design, laying configuration and environment.

Knowing the temperature of the conductor and the load, the following predictions can be made:

- Time before maximum temperature is reached, given a permanent or dynamic load pattern and the maximum conductor temperature limit for the cable

- Temperature of the cable at the end of a given period of (over) load

- Maximum ampacity of the cable, given the duration (time) and the allowable temperature during an emergency situation.

(Note: DCR is also known as RTTR and DRS)

|

Omnisens Cobra monitors temperature all along the cable.

Thanks to its distance range the interrogator can be housed many kilometers from the asset. It is available in a range of cabinets, with battery, UPS and server options. An optical switch provides up to 20 channels so that several cables can be monitored from the same interrogator. Alerts can be sent to SCADA via TCP or relays, all standard Communications Protocols are available including IEC 61850. The interrogator is usually housed in the control/ instrument room on- or offshore. Portable versions are available for surveys onshore or from a vessel. |

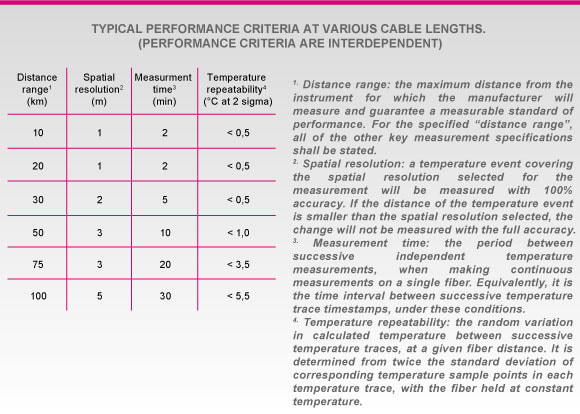

Note: Measurement definitions - Omnisens uses SEAFOM-MSP-01 Measurement Specification for Distributed Temperature Sensing (Download the document here).

Omnisens Cobra can grow with your project. A range of interrogators and optical switches to monitor up to 20 channels means the Omnisens Cobra system will expand as additional cables are added to the offshore windfarm or interconnector system.

|

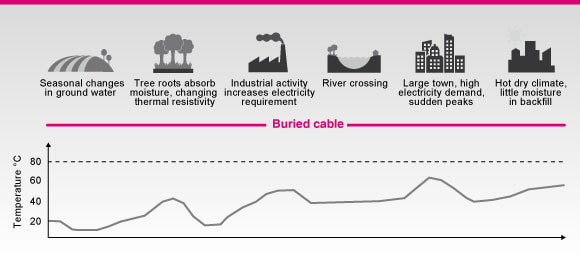

Over time, the soil or environment around a buried cable alters resulting in changes to the cable’s ability to dissipate heat. Cables in ducts or tunnels can also be affected.

|

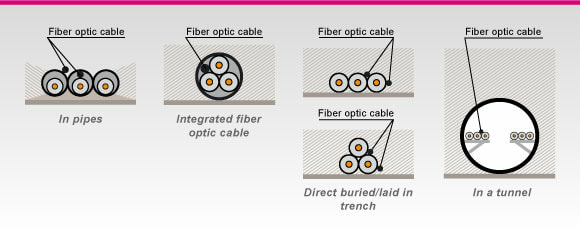

To monitor the temperature of energy cables, the optical fiber sensing cable is either integrated within the energy cable, attached to it, or placed close by. A nearby existing communications cable can also be employed. The sensing fibers should be single mode (communications grade) fiber for an Omnisens

DITEST or multimode fiber for an Omnisens Raman based system. |

Temperature monitoring of cables pinpoints developing temperature events in real time. An intervention can then be directed to the part of the cable concerned, reducing the risk of subsequent failure. Adding Dynamic Cable Rating, the cable can be safely loaded according to actual temperature, rather than the steady state rating.

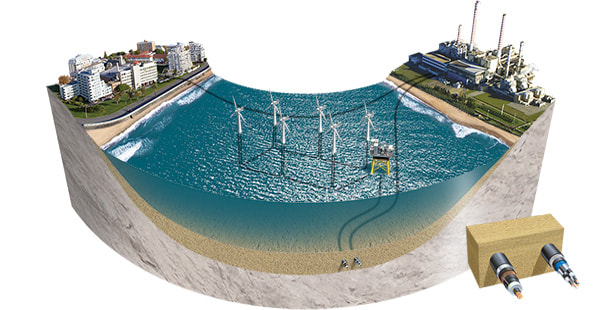

Export, array, power-from-shore and interconnector cables

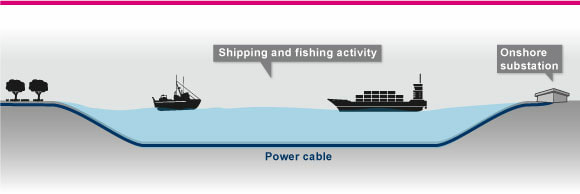

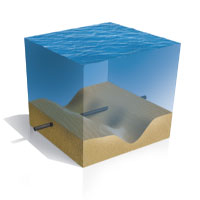

Currents, moving sea and riverbeds, diurnal and seasonal temperature changes, fishing, shipping and submarine activities all threaten subsea cable integrity.

|

Damage to the cable or changes in its environment can be inferred from the cable’s temperature, all along its length, using optical fibers within the cable. If the cable is stretched or damaged resulting in the optical fiber breaking, an alert will be sent indicating the location of the break so that the repair team can plan appropriately.

Omnisens Cobra has a range of Distributed Temperature Sensing (DTS) interrogators to monitor all cable lengths. A Brillouin based DITEST can monitor up to 100 km (solutions are available for longer distances). Since the interrogator can be placed some distance from the cable, for windfarms, the interrogator can usually be housed onshore. Free from dependence on weather windows or offshore qualified personnel for maintenance, opex is reduced and there is no offshore capex. |

Cable exposure (un-burial)

|

Power-from-shoreThe power-from-shore cable includes a dynamic section below the hang-off point. The bend stiffener, component friction and touchdown point protection may contribute to unforeseen effects on the cable temperature.

Areas of higher temperature can be identified as separate zones in the Cobra system with alerts set accordingly, giving the operator early warning of unplanned temperature excursions. This information can also be included in the feedback to the cable model to help predict service life. |

|

SURVEYS

Omnisens systems are available for rent. Training and a service engineer can be provided with a rental system. A survey can be helpful for troubleshooting, cable investigations and for providing a pre-energization profile of a cable. Omnisens DITEST is available for optical fiber quality testing during cable manufacture. APPLICATION ENGINEERING Specialists are available to ensure that the Omnisens system corresponds to client requirements, via:

|

COMMISSIONING AND INSTALLATION

SERVICE CONTRACTS A range of services ensures continuous availability of the monitoring system. These include:

|